Strona główna » Hydrocarbon Separators » Coalescing/lamellar separator class I according to PN EN 858 PETRO-G/GL

Coalescing/lamellar separator class I according to PN EN 858 PETRO-G/GL

The device is made of glass fiber reinforced polyester with orthophthalic resins.

Compliant with PN-EN 858-1:2005; PN-EN 858-1:2005/A1:2007 standards.

No need for retaining walls.

Installation: underground/aboveground (freestanding).

Fiberglass reinforced polyester cover, 100% sealed, not intended for pedestrian or vehicular traffic.

620 mm diameter manhole.

Ø75 mm ventilation placed according to customer’s requirements.

Operating principle:

Hydrocarbon separators of the PETRO-G series capture hydrocarbon substances contained in rainwater.

The coalescing filter (PETRO-G) or lamellar filter (PETRO-GL) ensures a reduction of hydrocarbon substances to 5 mg/liter at the outflow, in accordance with PN-EN 858-1 standard.

The automatic closure system prevents hydrocarbon substances from entering the outflow waters, even in the case of heavy rainfall.

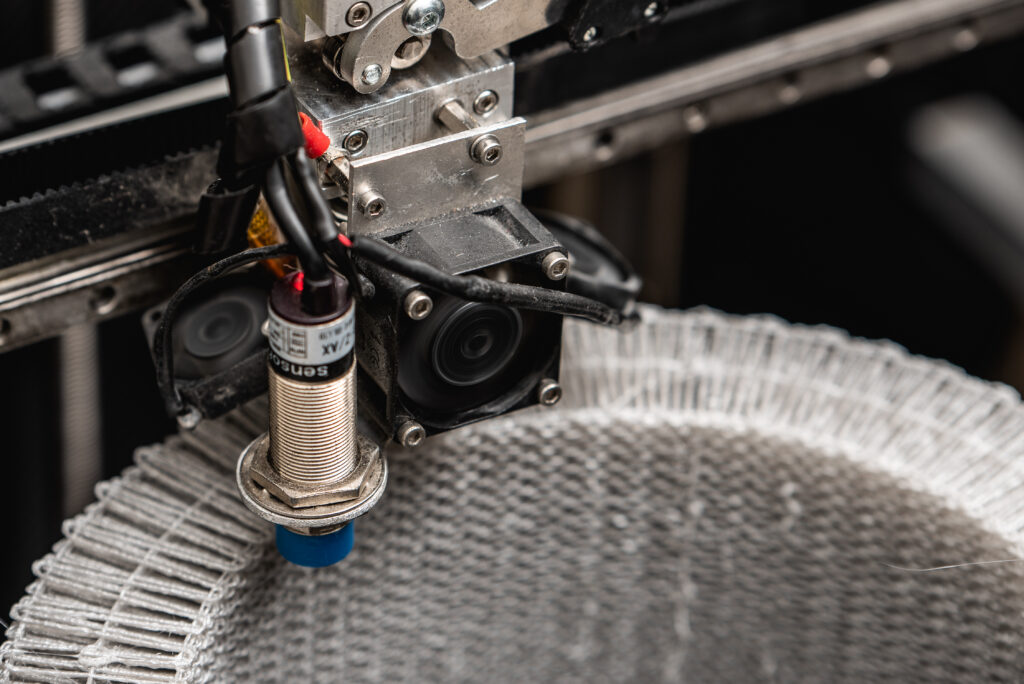

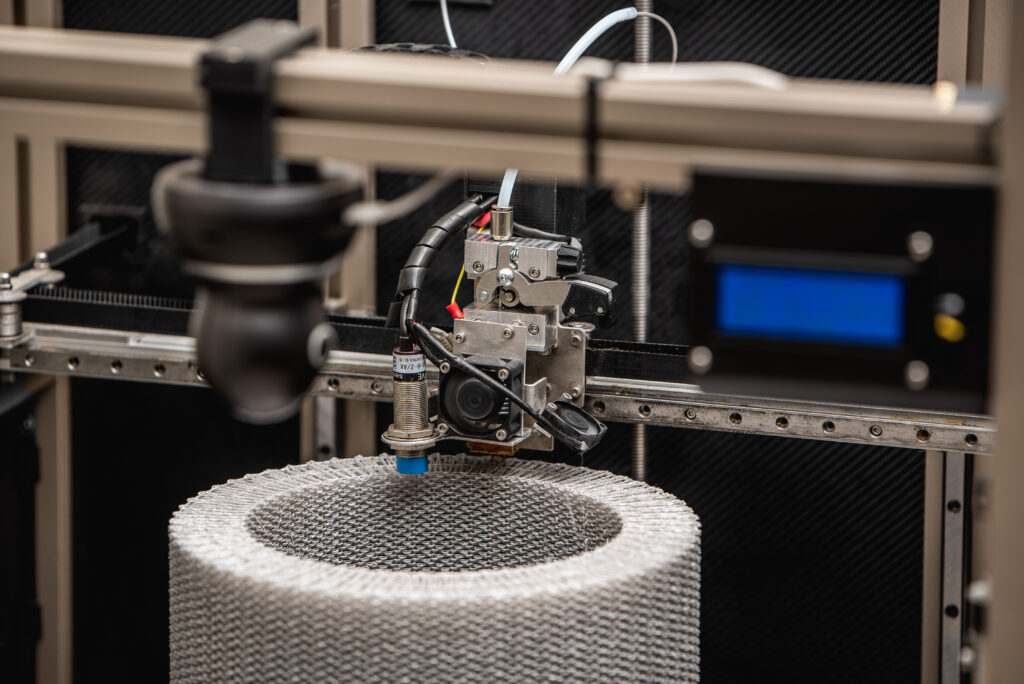

Innovative lamellar filter:

Specially designed cylindrical lamellas improve the coalescence process and significantly enhance the separator’s operation. Achieving a unique filter shape is possible thanks to 3D printing technology. Filters obtained in this way are characterized by high durability and contribute to environmental protection as they are made from PET material derived from bottle recycling.

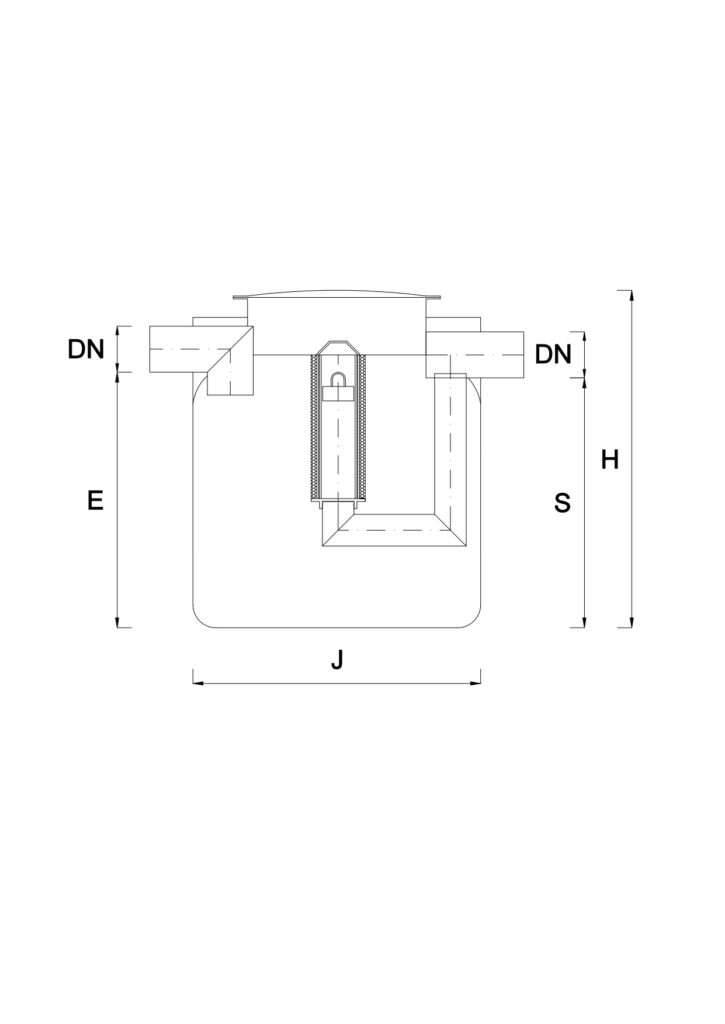

| Model | Przepływ Qnom | J | E | S | H | DN | Pojemność czynna całkowita | Waga separatora (około) |

| [l/s] | [mm] | [mm] | [mm] | [mm] | [mm] | [l] | [kg] | |

| PETRO-G/GL 5 | 5 | 1000 | 640 | 620 | 900 | 160 | 450 | 39 |

| PETRO-G/GL 7 | 7 | 1000 | 890 | 870 | 1150 | 160 | 650 | 45 |

| PETRO-G/GL 10 | 10 | 1000 | 1260 | 1240 | 1520 | 160 | 950 | 62 |

| PETRO-G/GL 15 | 15 | 1000 | 1890 | 1870 | 2150 | 160 | 1400 | 78 |

Operation The frequency of emptying the device depends on the intensity of incoming sewage. The tank chamber should be regularly emptied, at least twice a year or in case of alarm signaling. After each emptying, it is necessary to refill the separator with water.

Notes The volume of the separator should be selected in such a way that the temperature of the sewage flowing out of the separator does not exceed 40°C. Excessive temperature can cause damage to equipment behind the separator, such as pumps, floats (pump components have a temperature resistance of up to 40°C). In case of high sewage temperature, it is recommended to select a separator with double volume.

Customization Separators can also be customized according to individual projects, including:

- Different diameters of inlet and outlet pipes, changed dimensions of tanks, or angled inlets

- Separators integrated with pump chambers in horizontal tanks

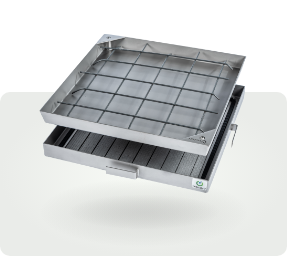

- Additional equipment such as a float valve at the inlet to the separator or stainless steel equipment

Might come in handy - Accessories

Biocent dla Ciebie

Jeżeli chcesz poznać lepiej Biocent zapisz się do naszego newslettera i bądź na bieżąco.

Masz pytania? Napisz do nas. Chętnie odpowiemy.

Z chęcią przyjmiemy Twoją wiadomość za pośrednictwem naszego formularza kontaktowego lub pocztą e-mail. Skontaktuj się z obsługą klienta Biocent, a odpowiemy najszybciej, jak to możliwe.

Sprawdź nasz FAQ

Poszukaj odpowiedzi w Naszej sekcji FAQ.