Strona główna » Sewage pumping stations

Sewage pumping stations

In areas where gravity sewage systems cannot be implemented (e.g., due to unfavorable terrain or existing construction obstacles), the only way to discharge sewage is by using sewage pumping stations. These stations are used for automatically pumping the medium to a higher and further located receiver (e.g., a surge well or an existing collector).

Sewage pumping stations

We install pumping stations in locations where gravity sewage systems cannot be implemented (e.g., due to unfavorable terrain or existing construction obstacles).

We design and customize them to specific conditions prevailing in each location.

We design and customize them to specific conditions prevailing in each location. All pumping station parameters are tailored to the client’s needs, project requirements, and actual conditions at the construction site.

By using a wide range of components, we can meet any requirements, and our design department is capable of selecting and designing any sewage pumping station.

All devices are manufactured in accordance with applicable standards, and as one of the few in the market, we have liability insurance for our pumping stations amounting to 3,000,000 PLN.

BUNDLIFT Water and Oil Separation System

Bundlift combines two devices working simultaneously – a single or double-pump sewage pumping station and an alarm system for detecting the thickness of oil-based substances in the rainwater collection tank (typically in the depression of an oil spillage tray under a transformer or in a well directly connected to the spillage tray).

It might come in handy - Accessories

BIOCONNECT Pumping Station Monitoring

Comprehensive and unique solution

Remote access via smartphone / tablet / PC

Our solution enables remote reading of sewage pumping station parameters such as: current status of pump activation and operation, float states, medium level, alarm statuses, ambient temperature. This information is presented graphically and through real-time charts.

Basic functions of the application

Remote activation, deactivation, and locking of pumps in pumping stations

Pump operation signaling (activation, deactivation)

Pump operation mode signaling (manual mode, automatic mode)

Float switch activation signaling (dry run, minimum level, maximum level, alarm level)

Pump alarm event signaling

Primary power supply failure signaling (switching to emergency power supply)

Reading of medium level and remote adjustment of individual level settings in pumping stations

Event history in table form (e.g., alarms)

Event history in graph form (pump activations, number of pump activations, pump operating time)

Report generation (e.g., daily, weekly, monthly)

Visualization of sewage pumping station locations on a map

Ability to send event information via SMS messages

Signaling of manhole and control cabinet door openings

Optional features

Current measurement of individual pumps

Reading of ambient temperature and tank interior temperature

Environmental monitoring using a camera system

Intruder detection system (seismic sensors)

Flow measurement

Signaling of manhole and control cabinet door openings

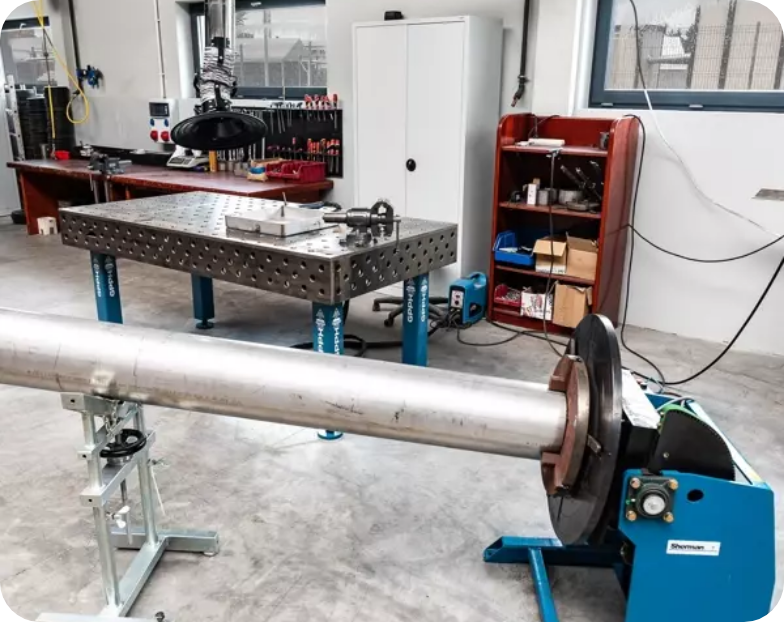

Custom Projects

We are also prepared to fully guarantee the proper operation of our devices both during the warranty period and after its expiration. The Biocent service is ready to quickly and efficiently respond in the event of pumping station malfunctions. We also offer periodic inspections of sewage pumping stations to ensure trouble-free operation. Devices entrusted to us for servicing are restored to usability as quickly as possible.

Service

We are also prepared to fully guarantee the proper operation of our devices both during the warranty period and after its expiration. The Biocent service is ready to quickly and efficiently respond in the event of pumping station malfunctions. We also offer periodic inspections of sewage pumping stations to ensure trouble-free operation. Devices entrusted to us for servicing are restored to usability as quickly as possible.

If you haven’t found a suitable pumping station for yourself, please contact our office.

FAQ - Sewage pumping stations

Who needs a home sewage pumping station?

A sewage pumping station is applicable wherever gravity sewage systems are not suitable. Special pumps enable the transport of pollutants from a lower level to a higher located tank. This is an ideal solution for facilities built, for example, in terrain depressions.

How do I know if the pumping station will meet my expectations?

When deciding to build a sewage pumping station, you want to be sure that it will perform its task flawlessly. We are well aware of this and therefore offer you comprehensive solutions that cover both the stages of project development and its implementation. Each time, we select appropriate elements according to the actual needs of our clients to give you the assurance that the end result will meet your expectations.

How can I monitor the condition of my pumping station?

If you want to have the ability to continuously monitor your home sewage pumping station, you can take advantage of the features provided by our remote monitoring system. With its help, you can check the status of individual parameters and any alarm events. All you need is an internet connection (e.g., on your computer or phone).

Does a home sewage pumping station cause unpleasant odors?

In the past, sewage pumping stations were associated with unpleasant odors. Nowadays, there are a number of amenities that allow for significant reduction or complete elimination of odor. This is possible thanks to the use of special materials, such as stainless steel and filters. Very good results are noticeable in the case of activated carbon filters.

How to properly maintain a sewage pumping station?

Regular maintenance of the sewage pumping station allows it to remain in good technical condition for many years. That’s why we offer periodic inspections and servicing of purchased equipment. To prevent major breakdowns, remember to systematically respond to any alarm states that appear. Our remote monitoring system will facilitate control over these events.

Biocent dla Ciebie

Jeżeli chcesz poznać lepiej Biocent zapisz się do naszego newslettera i bądź na bieżąco.

Masz pytania? Napisz do nas.

Chętnie odpowiemy.

Z chęcią przyjmiemy Twoją wiadomość za pośrednictwem naszego formularza kontaktowego lub pocztą e-mail. Skontaktuj się z obsługą klienta Biocent, a odpowiemy najszybciej, jak to możliwe.

Sprawdź nasz FAQ

Poszukaj odpowiedzi w Naszej sekcji FAQ.