Strona główna » Hydrocarbon Separators » Coalescing/lamellar separator Class I according to PN EN 858 PETRO-C/CL

Coalescing/lamellar separator Class I according to PN EN 858 PETRO-C/CL

Separators compliant with the PN-EN 858-1:2005; PN-EN 858-1:2005/A1:2007 standard

Coalescing (PETRO-C) / lamellar (PETRO-CL) filter and automatic closure preventing the overflow of petroleum substances

Tank body made of minimum class C40/50 reinforced concrete

Sulfate-resistant concrete Concrete permeability: < 5%

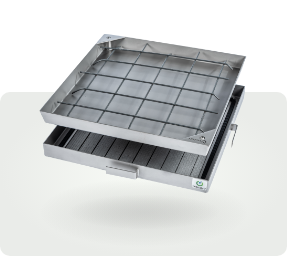

Concrete tightness: W10 Frost resistance F 150 Separators equipped with D400 class cast iron manholes

Nonslip cover for the separator D400

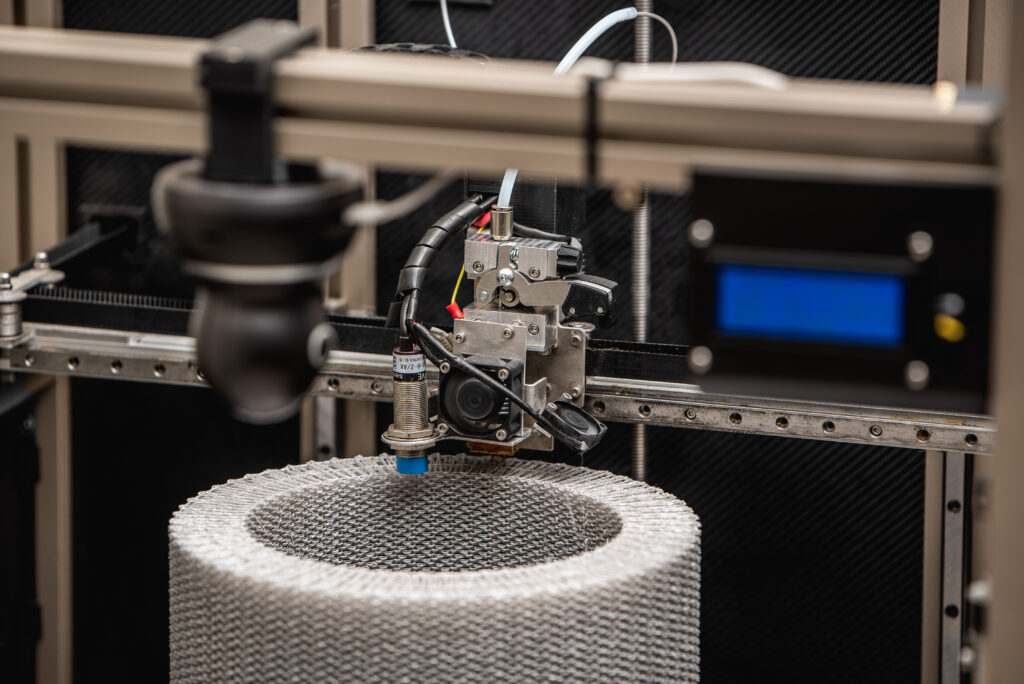

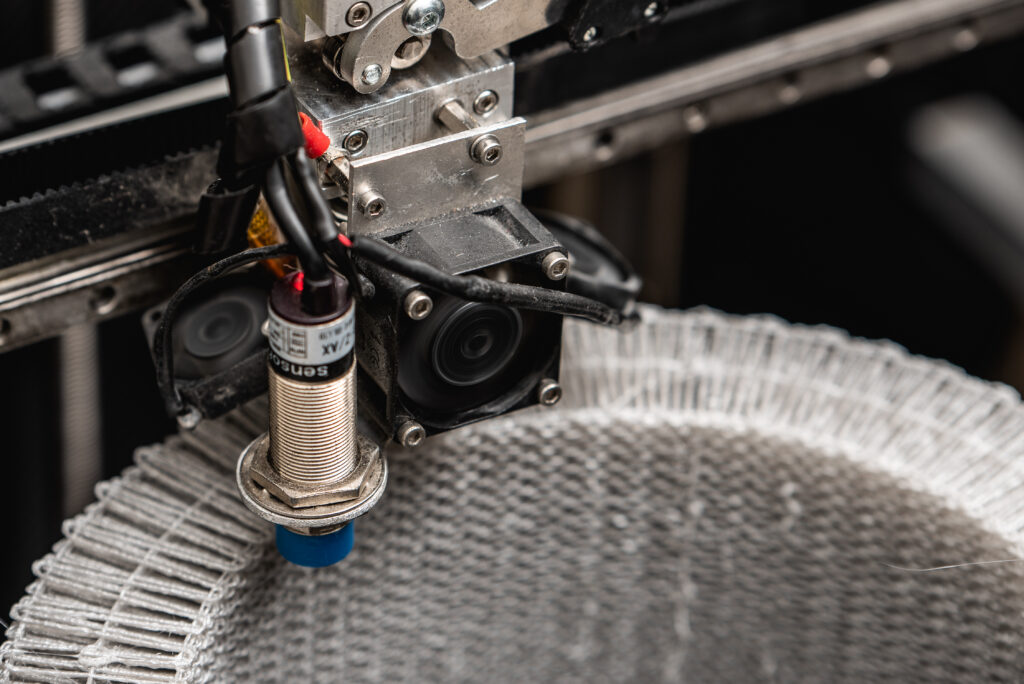

Innovative lamellar filter: Specially designed cylindrical-shaped lamellae improve the coalescence process and significantly enhance the separator’s operation. Achieving a unique filter shape is possible thanks to the application of 3D printing technology. Filters obtained in this way are characterized by high durability and contribute to environmental protection as they are made from PET material originating from bottle recycling.

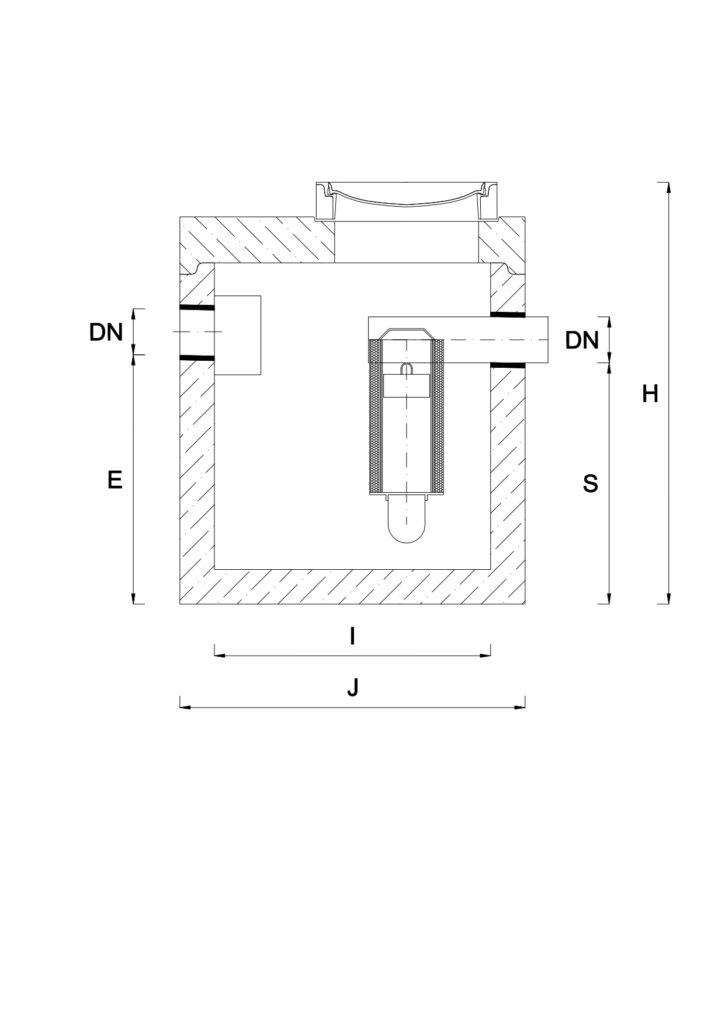

| Model | Przepływ Qnom | Średnica zewnętrzna J | Średnica wewnętrzna I | Wysokość wlotu E | Wysokość wylotu S | Wysokość całkowita H | Średnica wlotu DN | Pojemność czynna całkowita | Waga najcięższego el. (około) |

| [l/s] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [l] | [t] | |

| PETRO-C/CL 4 | 4 | 1300 | 1000 | 640 | 610 | 1350 | 160 | 360 | 1.65 |

| PETRO-C/CL 6 | 6 | 1300 | 1000 | 840 | 810 | 1550 | 160 | 520 | 1.92 |

| PETRO-C/CL 8 | 8 | 1300 | 1000 | 1040 | 1010 | 1750 | 160 | 675 | 2.2 |

| PETRO-C/CL 10 | 10 | 1300 | 1000 | 1240 | 1210 | 1950 | 160 | 830 | 2.5 |

| PETRO-C/CL 15 | 15 | 1500 | 1200 | 1300 | 1270 | 2050 | 200 | 1265 | 3.15 |

| PETRO-C/CL 20 | 20 | 1500 | 1200 | 1600 | 1570 | 2350 | 200 | 1605 | 3.6 |

| PETRO-C/CL 25 | 25 | 1500 | 1200 | 1950 | 1920 | 2750 | 250 | 2000 | 4.25 |

| PETRO-C/CL 30 | 30 | 1800 | 1500 | 1585 | 1555 | 2450 | 315 | 2480 | 4.75 |

| PETRO-C/CL 40 | 40 | 1800 | 1500 | 1985 | 1955 | 2850 | 315 | 3190 | 5.5 |

| PETRO-C/CL 50 | 50 | 2300 | 2000 | 1485 | 1455 | 2350 | 315 | 4100 | 6.25 |

| PETRO-C/CL 60 | 60 | 2300 | 2000 | 1785 | 1755 | 2650 | 315 | 5040 | 7.0 |

| PETRO-C/CL 80 | 80 | 2800 | 2500 | 1485 | 1455 | 2350 | 315 | 6400 | 6.8 |

| PETRO-C/CL 100 | 100 | 2800 | 2500 | 1900 | 1870 | 2850 | 400 | 8440 | 8.0 |

Service

The frequency of emptying the coalescing separator depends on the intensity of incoming sewage. The tank chamber should be regularly emptied, at least twice a year or in case of an alarm signal. After each emptying, it is necessary to refill the separator with water.

Customization

It is also possible to manufacture coalescing separators with or without a sedimentation tank according to an individual project, including: – Made of powder-coated S235 steel or stainless steel AISI 304, AISI 316 – Dimensions tailored to individual needs

Proper selection of the oil separator is possible after familiarizing oneself with the specific models available in our offer.

Might come in handy - Accessories

Overflow and contamination level alarm

DN 65 emptying installation

Sealed hatch for filling BKP

Cast iron hatches class A15-D400

Biocent dla Ciebie

Jeżeli chcesz poznać lepiej Biocent zapisz się do naszego newslettera i bądź na bieżąco.

Masz pytania? Napisz do nas. Chętnie odpowiemy.

Z chęcią przyjmiemy Twoją wiadomość za pośrednictwem naszego formularza kontaktowego lub pocztą e-mail. Skontaktuj się z obsługą klienta Biocent, a odpowiemy najszybciej, jak to możliwe.

Sprawdź nasz FAQ

Poszukaj odpowiedzi w Naszej sekcji FAQ.